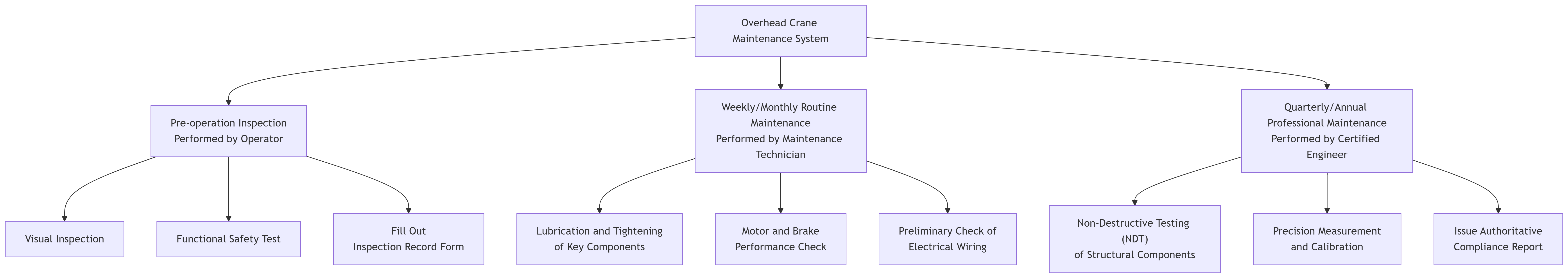

1. Maintenance Types and Frequency

Maintenance for overhead cranes is typically divided into three levels, with their cycles and responsible personnel as shown below:

2. Daily Inspection (Performed by the Operator)

Operators should perform the following checks before each shift or use:

1. Visual Inspection:

Structural Components: Check the main girder, end trucks, and legs for visible cracks, deformation, or corrosion.

Wire Rope/Chain: Look for broken wires, kinks, crushing, corrosion, or excessive wear.

Hook: Check the throat opening, wear, and ensure the latch is intact and functional.

Sheaves: Check the rim for damage or cracks, and ensure groove wear is within limits.

2. Functional Safety Tests:

Brakes: Test the braking performance of the hoisting, bridge, and trolley travel mechanisms under no load to ensure no hook or trolley drifting.

Limit Switches: Test the upper hoist limit and travel limit switches for proper and responsive operation.

Emergency Stop Buttons**: Test all emergency stop functions.

Unusual Noises: Listen for abnormal noises or vibrations from motors, gearboxes, wheels, etc., during operation.

3. Record Keeping: Report any abnormalities immediately and fill out the daily inspection checklist.

3. Periodic Maintenance (Performed by Maintenance Technicians)

Weekly/Monthly Maintenance:

1. Lubrication:

Lubricate all points according to the manufacturer's chart using the specified type of oil/grease.

Key points: wire rope, sheave bearings, wheel bearings, gear couplings, gearbox.

2. Tightening: Check and tighten all visible bolted connections, especially foundation bolts, rail clamp bolts, trolley connection bolts, etc.

3. Brake Adjustment: Check brake lining wear, adjust the clearance between the brake shoe and the brake drum to the specified value. Replace severely worn linings.

4. Electrical Check: Check controller contacts for burning, cable insulation for damage, and terminal connections for looseness.

Quarterly/Biannual Maintenance** (More in-depth inspection):

1. Wheels: Check wheel treads for wear or spalling, and check flange thickness. Measure wheel diameter differences to ensure conformity on the same axle.

2. Runway Rails: Check rail fixation, measure gauge, alignment, and elevation errors to ensure they are within allowable limits.

3. Gearbox: Check the oil level and quality, replace if necessary. Listen for gear meshing sounds.

4. Motor: Check motor bearing operation sounds and measure insulation resistance.

4. Annual Inspection (Performed by Professional Engineers)

The annual inspection is a comprehensive and thorough check, often requiring collaboration with special equipment inspection agencies:

1. No-Load Test: Check the normal operation of all mechanisms.

2. Rated Load Test: Test crane performance under rated load.

3. Dynamic Load Test (Typically 1.1 times the rated load): Verify the load-bearing capacity of the mechanisms and structure.

4. Static Load Test(Typically 1.25 times the rated load): Check the structural strength of the crane and its components.

5. Non-Destructive Testing (NDT): Perform magnetic particle or ultrasonic testing on key welds (e.g., connections between main girder and end trucks), hooks, sheave pins, etc., to detect internal defects.

6. Dimensional Accuracy Measurement: Measure main girder camber, sweep, etc., to confirm they are within allowable tolerances.

7. Comprehensive Electrical Inspection: Check the performance and insulation of all electrical components.

5. Common Failures and Troubleshooting

| Symptom | Possible Cause and Action |

| Crane runs skewed, track gouging | Check for consistent drive wheel diameters on both sides, motor synchronization, and excessive runway misalignment. |

| Brake slipping or insufficient force | Adjust brake clearance, replace worn brake linings, check hydraulic thruster for low fluid or leaks. |

| Hoist load drifting | Stop use immediately! Check hoist brake, gearbox, or coupling. |

| Abnormal noise | From motor: Bearing failure or phase loss; From gearbox: Gear wear or lack of oil; From wheels: Obstruction on rail or damaged wheel. |

| Controller malfunction | Check contacts, wiring connections, or for voltage instability. |

6. Maintenance Records and Management

Establishing a sound maintenance record system is crucial. Records should include:

Daily inspection checklists

Periodic maintenance records

Annual inspection reports

Failure repair records

Component replacement records

These records are not only a compliance requirement but also form the basis for failure analysis and predictive maintenance.