An overhead crane is a complex system, and its parts can be categorized into three major groups: the bridge, the hoist/trolley, and the end trucks.

1. The Bridge

This is the main horizontal beam that forms the "bridge" of the crane. It spans the width of the bay and travels along the runway rails. Its primary component is the Girder(s).

Single Girder: One bridge beam, where the hoist trolley runs on the bottom flange. Cost-effective for lighter capacities (typically up to 20 tons) and shorter spans.

Double Girder: Two bridge beams, with the trolley running between them on a rail mounted to the top of the girders. Used for heavier capacities (20 tons and far beyond), longer spans, and more demanding duty cycles. Offers higher hook height.

2. The End Trucks

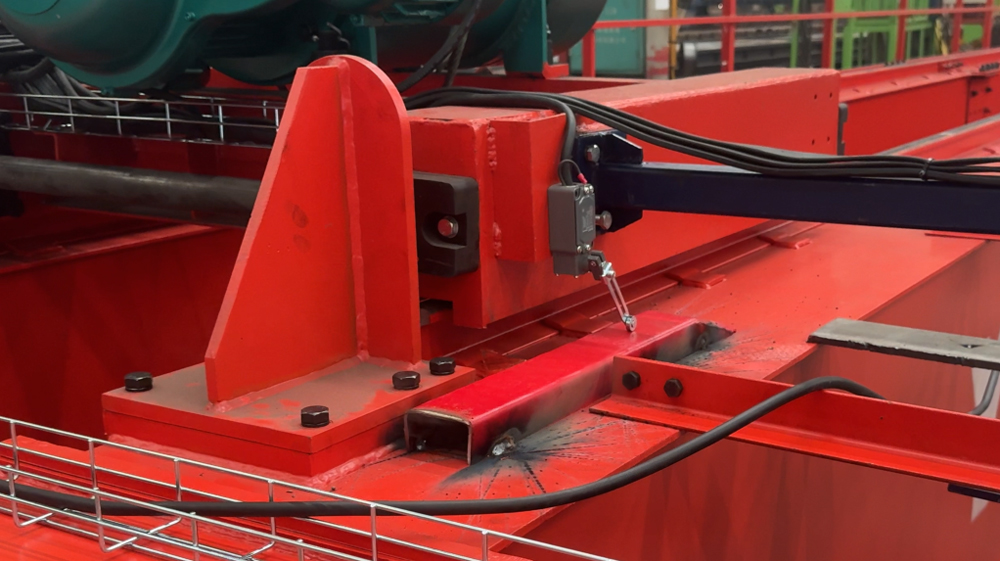

Located at each end of the bridge, these assemblies house the wheels, bearings, and axles that allow the entire crane to move longitudinally along the runway rails.

Wheels: Forged or cast steel wheels that ride on the runway rails. Their size and hardness are critical for bearing the crane's load.

Drive Motors: One or more motors that provide power to the wheels for bridge travel (also called "long travel").

Bumpers: Rubber or spring-loaded devices mounted on the end trucks to absorb impact in case of over-travel.

3. The Hoist

This is the component that does the actual lifting and lowering of the load. It is the heart of the crane.

Motor: The electric or hydraulic motor that provides the power for lifting and lowering.

Brake: A critical safety device that holds the load automatically when the hoist motor is not powered. Typically fails-safe (engages when power is lost).

Gearbox: Reduces the high speed of the motor to a usable, powerful speed for lifting.

Drum or Sheaves: The hoist unit either has a drum around which the wire rope is wound, or uses a system of sheaves (pulleys) for a chain hoist.

Hook: The forged or alloy steel point of attachment for the load. It must be regularly inspected for cracks or deformation.

4. The Trolley

The trolley is the frame that carries the hoist. It moves laterally across the bridge girders, allowing for precise positioning of the load across the width of the bay.

Trolley Frame: The structure that supports the hoist.

Trolley Drive Motor: The motor that powers the movement of the trolley across the bridge ("cross travel").

Trolley Wheels: Wheels that run on a rail attached to the bridge girder(s).

5. Runway System

This is the fixed infrastructure that supports the crane. The crane is only as good as its runway.

Runway Rails: The heavy-duty steel rails (often similar to railroad tracks) mounted on the runway beams. The crane's end truck wheels travel on these.

Runway Beams: The structural steel beams (often attached to the building's columns) that support the rails and carry the entire weight of the crane and its load.

6. Electrical System & Controls

The nervous system of the crane, providing power and command.

Main Festoon System / Conductor Bars: The system that delivers power from the building's source to the crane itself as it moves. Festoon systems use a coiled cable, while conductor bars use rigid bars with collectors.

Crane Control Panel (Cabinet): Houses the contactors, variable frequency drives (VFDs), and overload protection devices.

Operator Control: How the crane is commanded.

Pendant Station: A hanging control box with buttons, operated by a worker on the floor. Most common.

Cab Operated: The operator sits in a cab mounted to the crane.

Radio Remote Control: A wireless, portable transmitter allows the operator to control the crane from the safest and most optimal location on the floor.

7. Safety Devices

These are non-negotiable, critical components.

Load Limiters: Automatically cut power to the hoist if an attempt is made to lift beyond the crane's rated capacity.

End Stops/Limit Switches: Automatically cut power to the bridge or trolley drive motors at the end of the permitted travel to prevent over-travel and collisions.

Emergency Stop (E-Stop): A prominently located button to cut all power to the crane immediately.

Warning Devices: A horn or beacon to alert personnel that the crane is in motion.

Every part of an overhead crane plays a vital role. The structural components (bridge, end trucks, runway) provide support and movement, the mechanical component (hoist) performs the lifting, and the electrical and safety systems provide control and protect both the equipment and personnel. Regular inspection and maintenance of all these parts are crucial for safe and reliable operation.