EDS Double girder electric hoists equipped with main and auxiliary hooks are designed for versatile heavy-duty lifting, balancing high-capacity handling with operational efficiency. Below is a detailed breakdown of their features, applications, and safety considerations based on industry standards and case studies:

1. Functional Differences Between Main and Auxiliary Hooks

Main Hook

High Capacity & Low Speed:

Handles heavy loads (e.g., 16–800 tonnes), with lifting speeds typically 1–5 m/min to ensure stability.

Used for primary lifting tasks, such as moving steel coils, machinery, or large containers.

Structural Design:

Larger hook dimensions and multi-sheave pulley systems (e.g., 4–6 sheaves) to distribute load stress.

Auxiliary Hook

Lightweight & High Speed:

Lifts lighter loads (typically 1/5–1/3 of the main hook’s capacity, e.g., 3.2–160 tonnes) at faster speeds (5–20 m/min).

Ideal for precision tasks like positioning small components or handling lightweight bulk materials.

Flexibility:

Operates independently or assists the main hook in complex maneuvers (e.g., tilting cargo during steel pouring).

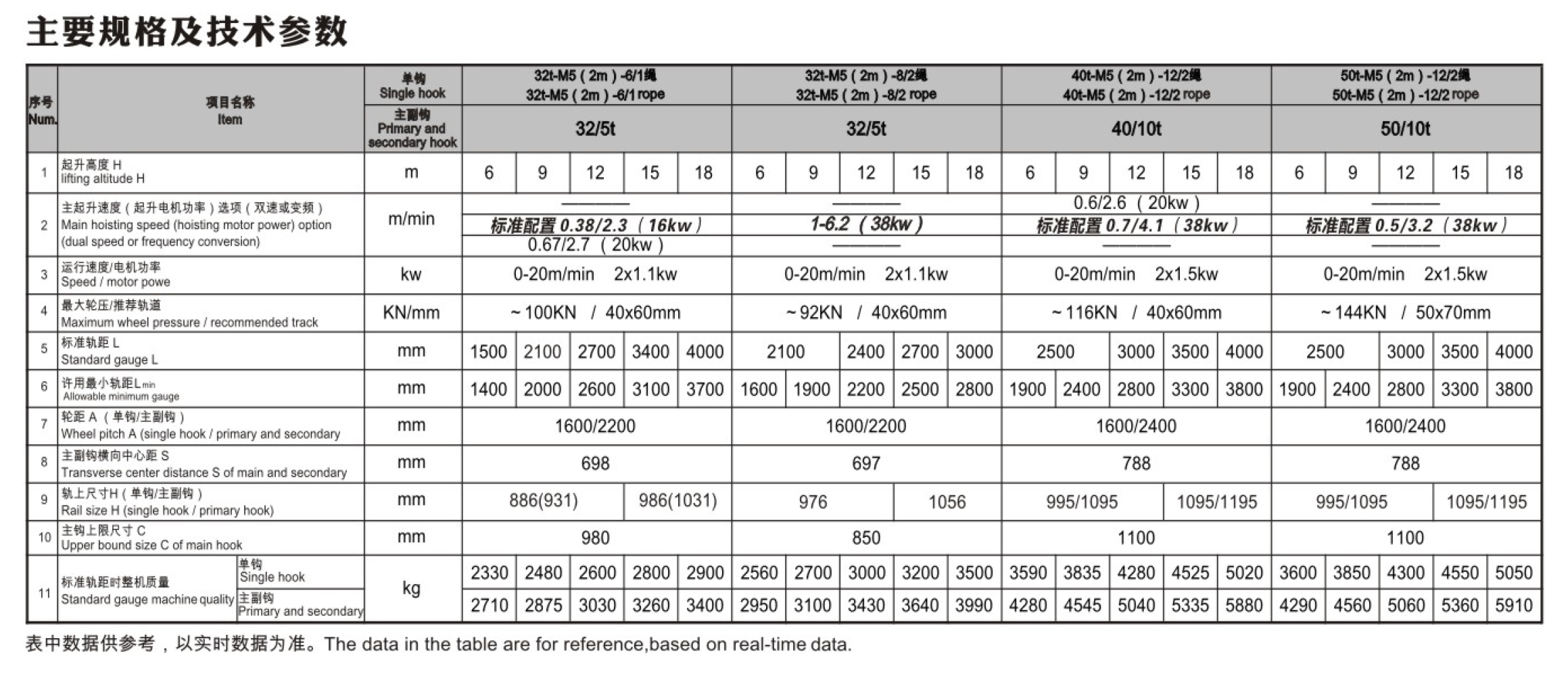

2. Technical Specifications

ParameterMain HookAuxiliary Hook

Lifting Capacity16–800 tonnes3.2–160 tonnes

Speed Range1–5 m/min5–20 m/min

Pulley SystemMulti-sheave (4–6)Single/double sheave

Control ModeVariable frequency driveStandard contactor

3. Operational Guidelines

Safety Protocols

Independent Operation:

Avoid simultaneous use of both hooks unless explicitly designed for coordinated tasks (e.g., steel pouring).

Non-active hooks must be raised to their upper limits to prevent collisions.

Overload Protection:

Sensors trigger automatic shutdowns if the combined load exceeds the main hook’s capacity.

Typical Workflows

Steel Pouring:

The main hook lifts the ladle, while the auxiliary hook adjusts its tilt angle to control molten metal flow.

Warehouse Logistics:

Use the auxiliary hook for rapid pallet handling and the main hook for stacking heavy containers.

4. Industry Applications

Steel Mills:

Main hook transports molten metal ladles (16–32 tonnes), while the auxiliary hook positions molds.

Ports:

Auxiliary hook rapidly unloads lightweight cargo (e.g., timber), freeing the main hook for containers.

Manufacturing:

Dual hooks enable parallel workflows (e.g., assembling machinery while transporting parts).

Yes, because the working condition are different, all our products are customized depending on detail requirement! So all your products will be specially designed by our engineers according to your workshop conditions.

Yes, all kinds of certification are available, if you have doubt, you can come to our factory and test it by yourself,or you can let some third-partied to do the inspection for you.

Yes, we have. But we only have the standard-sized products, if you need customized products, then it will take some time to manufacture it.

It depends on your products quantity and products data you given, but we will try our best to deliver your products as soon as possible.

We will sent you the detail installation manual or if you are needing, our installation engineers can come to your workshop to guide the installation.

You can come to our factory anytime when you are convenient. We will make arrangement to pick you up.