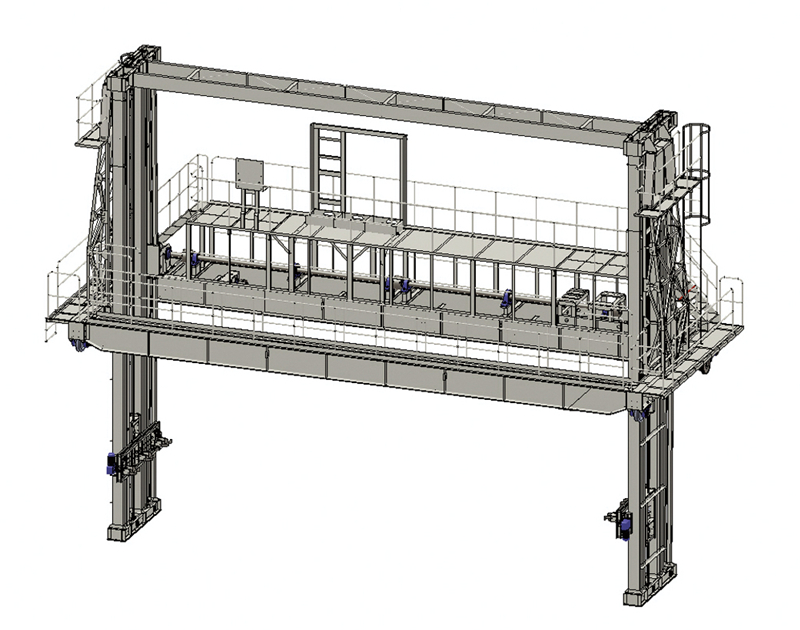

A Full Auto Aluminum Profile Oxidizing Line Overhead Crane is a specialized lifting solution designed for use in aluminum processing facilities, particularly those involved in the oxidation or anodizing of aluminum profiles. This type of crane is essential for efficiently moving and positioning aluminum profiles through various stages of the oxidation process.

Automation: The crane operates fully automatically, ensuring consistent and precise movement of materials throughout the production line.

Aluminum Profile Handling: Designed specifically to handle long and delicate aluminum profiles without causing damage or scratches.

Corrosion Resistance: Often built with materials resistant to corrosion, such as stainless steel components or coatings, to withstand chemical environments associated with anodizing processes.

High Precision Control : Equipped with advanced control systems that allow for precise positioning and smooth operation, reducing vibrations that could affect product quality.

While specific technical details may vary depending on the manufacturer and application requirements, here are some general specifications:

| Parameter | Value |

|---|---|

| Lifting Capacity | Typically up to 10 tons |

| Span | Customizable (commonly 10-20 meters) |

| Lifting Height | Up to 15 meters |

| Automation Level | Fully automated |

| Control Method | PLC-based automation |

Aluminum Anodizing Plants : Used extensively in facilities where aluminum profiles undergo surface treatment processes like anodization.

Oxidation Lines: Essential for moving profiles through different stages of oxidation treatment.

>Material Handling Systems: Integrated into larger material handling systems within manufacturing plants.

Efficiency Enhancement: Automates material movement, significantly increasing production efficiency by minimizing manual labor.

Precision Handling: Ensures careful handling of delicate products like aluminum extrusions during processing stages.

Safety Features: Incorporates safety measures such as collision detection systems and emergency stops to prevent accidents.

Customization Options: Can be tailored according to specific plant layouts and operational needs.

The Full Auto Aluminum Profile Oxidizing Line Overhead Crane plays a crucial role in maintaining efficient workflow while ensuring product integrity during complex chemical treatments like oxidation or anodization processes in the aluminum industry.

Yes, because the working condition are different, all our products are customized depending on detail requirement! So all your products will be specially designed by our engineers according to your workshop conditions.

Yes, all kinds of certification are available, if you have doubt, you can come to our factory and test it by yourself,or you can let some third-partied to do the inspection for you.

Yes, we have. But we only have the standard-sized products, if you need customized products, then it will take some time to manufacture it.

It depends on your products quantity and products data you given, but we will try our best to deliver your products as soon as possible.

We will sent you the detail installation manual or if you are needing, our installation engineers can come to your workshop to guide the installation.

You can come to our factory anytime when you are convenient. We will make arrangement to pick you up.