The HC/HM Fixed Wire Rope Electric Hoist series is designed for industrial lifting applications, offering versatility, durability, and precision. Below is a detailed breakdown of its key features, technical specifications, and applications based on the search results:

Key Features

Speed Variants:

HC Model: Single-speed operation (normal speed) for standard lifting tasks.

HM Model: Dual-speed (normal + low speed) for precise operations like sandbox mounding, machine maintenance, or delicate loading/unloading. This makes HM more adaptable to specialized tasks.

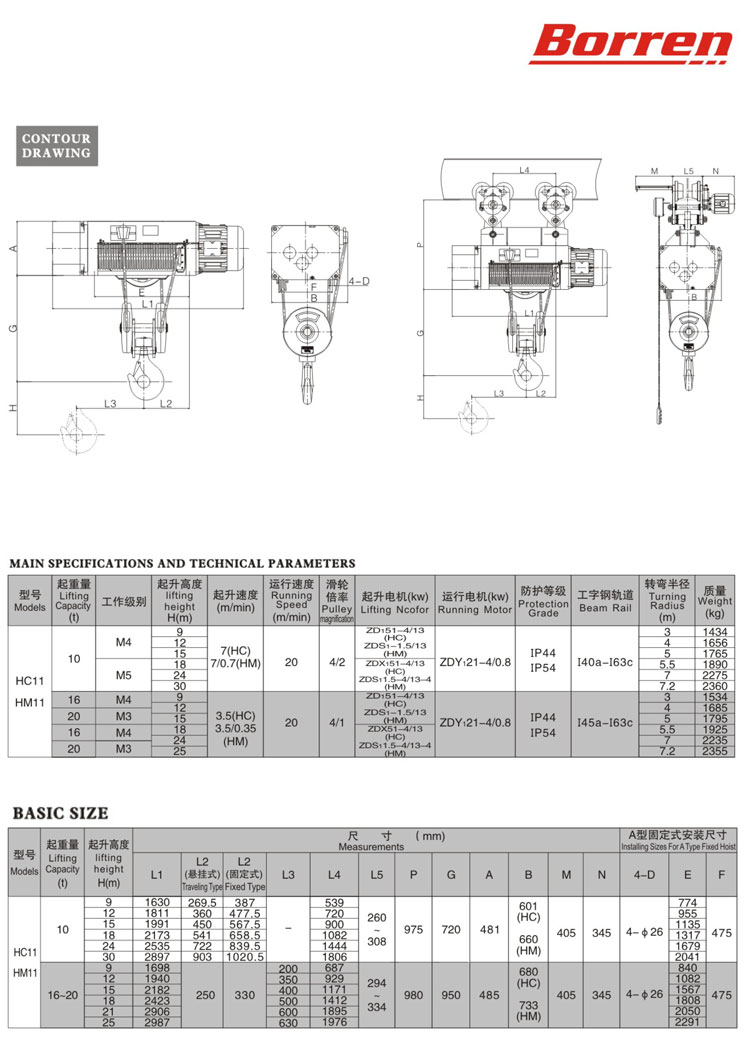

Lifting Capacity & Height:

Capacity: Ranges from 0.5 tons to 100 tons (HC25 model), with standard HC/HM models typically covering 16–100 tons.

Height: Up to 30 meters for standard HC/HM models, though some variants (e.g., HC08/16/25) extend to 60 meters.

Structural Design:

Compact, lightweight, and modular construction for easy installation on fixed frames, I-beam tracks, or integrated with cranes (e.g., gantry, double girder) .

Reinforced weld-formed frames for higher impact resistance compared to bolted joints.

Control Systems:

Operated via pendant pushbuttons, wireless remote control, or central control systems.

Safety features include overload protection, emergency stops, voltage protection, and braking systems (AC/DC brakes available for noise reduction) .

Technical Specifications

ParameterHC ModelHM Model

Speed0.3–8 m/minDual-speed: 8/0.8 m/min

Duty ClassA3 (medium duty)A3–A5 (heavy duty)

Ambient Temperature-20°C to 40°C-20°C to 40°C

CertificationsCE, ISO, SGS, BVCE, ISO, SGS, BV

Power Supply220V–440V, 50/60 Hz220V–440V, 50/60 Hz

Applications

Fixed Installations: Static setups in workshops, warehouses, or construction sites. Some models can later be upgraded with trolleys for mobility.

Marine & Ports: HC-C/HM-C variants are tailored for shipyards, docks, and offshore environments.

Heavy-Duty Industrial Use: Compatible with double girder cranes, gantry cranes, and specialized tasks like metallurgy or nuclear plant maintenance.

Precision Tasks: HM models excel in low-speed operations, such as aligning machinery or handling fragile materials.

Safety & Compliance

Overload Protection: Integrated sensors and polyurethane buffers to prevent mechanical failure.

Braking Systems: Options for AC (90–100 dB) or DC brakes (70–80 dB) for noise-sensitive environments. DC brakes (e.g., INTORQ) offer faster reaction times and durability.

Environmental Tolerance: Operates in humidity ≤85% (+25°C) and non-corrosive environments.

After-Sales: Warranty (1 year), free technical training, 24/7 support, and low-cost maintenance post-warranty .

Comparison with Other Models

CD1/MD1 Series: Older designs with lower capacities (0.5–50 tons) and fewer speed options. HC/HM models offer higher customization and advanced safety features.

Explosion-Proof Variants: Available for hazardous environments, though not explicitly mentioned in HC/HM specifications .

Yes, because the working condition are different, all our products are customized depending on detail requirement! So all your products will be specially designed by our engineers according to your workshop conditions.

Yes, all kinds of certification are available, if you have doubt, you can come to our factory and test it by yourself,or you can let some third-partied to do the inspection for you.

Yes, we have. But we only have the standard-sized products, if you need customized products, then it will take some time to manufacture it.

It depends on your products quantity and products data you given, but we will try our best to deliver your products as soon as possible.

We will sent you the detail installation manual or if you are needing, our installation engineers can come to your workshop to guide the installation.

You can come to our factory anytime when you are convenient. We will make arrangement to pick you up.